HEAVY-DUTY WHEEL GRINDER MACHINE

The Rebel 400RB60 is a compact heavy-duty wheel grinder designed for efficient deburring of cast iron and steel components. Stable, safe and ideal for medium to large foundries. Fully compliant with OSHA, CE and NR12

HEAVY-DUTY

The Rebel 400RB60 delivers excellent performance for medium-duty and heavy-duty grinding operations in foundries and metalworking plants. Its rigid structure, balanced wheel assembly and optimized motor configuration ensure smooth grinding with reduced operator fatigue. Suitable for cast iron, steel and ductile iron parts, the 400RB60 supports aggressive material removal as well as fine deburring. The machine is engineered for continuous operation and complies with OSHA, CE and NR12 safety standards. Typical applications include automotive castings, agricultural machinery components, hydraulic parts, and general industrial fabrication.

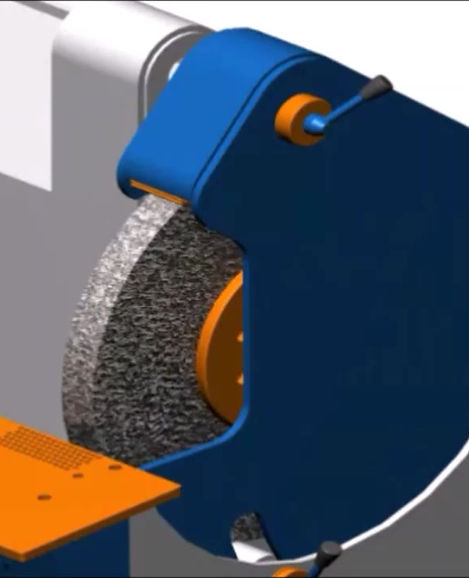

Grinder Machine Working with SuperAbrasive grinding Wheel

Grinder Machine Working with SuperAbrasive grinding Wheel

SUPERABRASIVE

GRINDING WHEEL

The Rebel Grinder was designed to operate with either organic or diamond grinding wheels, depending on its *configuration. With a quick setup process, the machine swiftly adapts to the required technical specifications, ensuring high performance and maximum safety.

*mechanical / electrical

TECHNICAL INFORMATION

400RB60

Model:

400RB60

Power:

7,5HP

Wheel size:

Diameter: Ø16" (406,4 mm)

Width: 2" or 2.5" (50.8 or 63.5 mm)

Internal diameter: 5" (127 mm)

Wheel speed:

63m/ sec.

SuperAbrasive:

Wheel Speed 80m/ sec.

Equipment weight:

450 kg.

AUTOMATIC BODYGARD SYSTEM

TO PROTECT THE OPERATOR IN CASE

OF WHEEL BREAKAGE.

500RB60

Model:

500RB60

Power:

10HP

Wheel size:

Diameter: Ø20" (508 mm)

Width: 2" or 2.5" (50.8 or 63.5 mm)

Internal diameter: 8" (203,2 mm)

Wheel speed:

63m/ sec.

SuperAbrasive:

Wheel Speed 80m/ sec.

Equipment weight:

500 kg.

AUTOMATIC BODYGARD SYSTEM

TO PROTECT THE OPERATOR IN CASE

OF WHEEL BREAKAGE.